TDC provides for all stainless steel materials, when properly maintained, a one-year warranty against all defects in workmanship and construction under normal wear and use of this product.

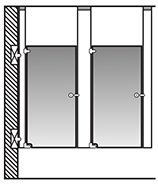

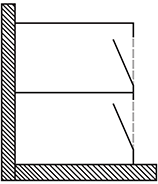

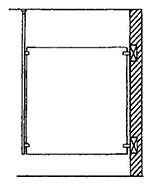

Ceiling Hung

The open style of this installation offers a unique blend of aesthetic and practical appeal. The absence of floor hardware provides a clean, contemporary design that will complement any washroom. The unobstructed access to floor also allows for simplified maintenance, making this style especially well-suited to washrooms having wall-hung fixtures. For proper installation of this partition style, structural steel ceiling supports are required.

Many options will influence the price of your partitions. To get an estimate, please contact us.

Powder-Coated

Stainless Steel

Solid Plastic (HDPE)

Plastic Laminate

Diamond Line

Powder-Coated

Powder coated steel partitions offer remarkable quality and durability at an affordable price. Electro-galvanized steel is bonded to a cellular honeycomb core with all edges interlocked and corners welded for maximum structural integrity. The thermosetting powder coating is electrostatically applied to ensure a uniform thickness and produces a finish that is highly resistant to fading, scuffing and staining. Availability in a wide range of contemporary colors makes it simple to find an option that will complement any washroom.

COMPOSITION / CONSTRUCTION OF MATERIALS

Doors are 1” thick, constructed with two 22-gauge sheets of stretcher leveled, commercial quality electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Panels are 1” thick, constructed with two 22-gauge sheets of stretcher leveled, commercial quality electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Type H/B –Headrail Braced Pilasters are 1-1/4” thick, constructed with two 20-gauge sheets of commercial quality electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. Edges are then interlocked with a continuous roll-formed edge molding. An inverted heavy gauge channel shall be welded into top of the pilaster for additional reinforcing. Pilasters shall have adjustable floor anchor system including an integral jack-leveling device. A polished 3” high stainless steel shoe of one-piece construction shall be supplied to conceal floor anchoring. Tamper proof shoe assembly held in place by means of concealed floor anchor clips –exposed screws are not acceptable. Pilaster tops are securely braced together with a continuous anti-grip headrail of extruded aluminum alloy, polished and clear anodized.

FINISH

Powder coated finishes are applied over electro-galvanized steel containing a zinc coating thickness of .00015”. All components shall be cleaned and degreased prior to application of powder for maximum finish adhesion. A hybrid epoxy/polyester powder is then applied by an electrostatic painting system to ensure uniform thickness. Baking at 345 degrees for 22 minutes cures the finish.

HARDWARE AND FITTINGS

All material components are fully prepared with suitable internal reinforcement to receive all necessary hardware and fittings. TDC Doors supplies factory pre-drilled components for a safer, more efficient and trouble-free installation. All door hinges and strike/keeper will be thru-bolted with sex bolts having theft resistant heads. Appropriate screws supplied for all other hardware and fittings. All fastenings to have a corrosion resistant finish.

Doors:

-Upper and lower door brackets are heavy non-ferrous Zamac castings that become integral part of door as they are imbedded within pre-formed abscesses at time of assembly. Powder coated finish shall match selected door color.

-Top hinge bracket (#102) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over the pilaster edge for maximum durability.

-Stainless steel pin (#101) goes through the door and the top hinge bracket for three-point bearing.

-Bottom hinge bracket (#103) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability. Door operates on opposing nylon cams that are fully recessed and concealed within the lower door bracket. The gravity activated cam assembly provides easy adjustment of door permitting it to rest at any desired open or fully closed position when not latched.

-Concealed latch assembly with stainless steel pin allows for emergency access. Cover plate and turn knob (#104) are heavy, non-ferrous Zamac castings with chrome plated finish. ADA lever handles are supplied on all handicap doors.

-Door strike and keeper (#105) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability.

-Combination coat hook and bumper for inswing doors (#106) or double-prong coat hook for outswing door (#107) shall be cast Zamac with chrome plated finish. Door pull (#109) shall be supplied on all outswing doors. ADA doors receive door pull on both interior and exterior faces. Door bumpers (#108) provided where required.

Wall and Pilaster Brackets:

-Shall be heavy, non-ferrous Zamac castings with chrome-plated finish. The wall anchored pilasters and dividing partition panels shall be attached with two brackets of either double ear or single ear design depending on existing wall condition. Dividing partition panels shall be attached to the “rear” pilaster face with two “U” brackets.

INSTALLATION

Shall be in accordance with TDC’s approved shop drawing and installation instructions with partitions being rigid, plumb, straight and level. Unless stated otherwise, doors and panels are 58” high and mounted 12” above finished floor. Pilasters shall measure 82” from floor to top of headrail.

Stainless Steel

For lasting beauty that blends into any washroom design and will easily withstand years of use, no matter how high-volume, stainless steel is the top choice. Resistant to corrosion, rust, staining, and offering simplified maintenance, this is an ideal option for any heavily trafficked washroom. Stainless Steel Partition material is available in a standard #4 brushed finish, or you may select from a number of optional textured finishes for greater durability and design appeal. Stainless Steel Partition material is available in any of the four design styles.

COMPOSITION / CONSTRUCTION OF MATERIALS

Doors are 1” thick, constructed with two 22-gauge sheets of stretcher leveled type 304 stainless steel #4 finish that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous stainless steel roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Panels are 1” thick, constructed with two 22-gauge sheets of stretcher leveled type 304 stainless steel #4 finish that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous stainless steel roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Type H/B –Headrail Braced Pilasters are 1-1/4” thick, constructed with two 20-gauge sheets of stretcher-leveled type 304 stainless steel #4 finish that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. Edges are then interlocked with a continuous stainless steel roll-formed edge molding. An inverted heavy gauge channel shall be welded into top of the pilaster for additional reinforcing. Pilasters shall have adjustable floor anchor system including an integral jack-leveling device. A polished 3” high stainless steel shoe of one-piece construction shall be supplied to conceal floor anchoring. Tamper proof shoe assembly held in place by means of concealed floor anchor clips –exposed screws are not acceptable. Pilaster tops are securely braced together with a continuous anti-grip headrail of extruded aluminum alloy, polished and clear anodized.

FINISH

All doors, panels and pilasters shall be type 304 stainless steel with a #4 finish and include a durable plastic film covering to safeguard them during shipment and installation. All components shall have vertical grain finish except panels wider than 58½” –seaming is not acceptable.

HARDWARE AND FITTINGS

All material components are fully prepared with suitable internal reinforcement to receive all necessary hardware and fittings. TDC supplies factory pre-drilled components for a safer, more efficient and trouble-free installation. All door hinges and strike/keeper will be thru-bolted with sex bolts having theft resistant heads. Appropriate screws supplied for all other hardware and fittings. All fastenings to have a corrosion resistant finish.

Doors:

-Upper and lower door brackets are heavy non-ferrous Zamac castings that become integral part of door as they are imbedded within pre-formed abscesses at time of assembly. Satin finish shall closely resemble door finish.

-Top hinge bracket (#102) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over the pilaster edge for maximum durability.

-Stainless steel pin (#101) goes through the door and the top hinge bracket for three-point bearing.

-Bottom hinge bracket (#103) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability. Door operates on opposing nylon cams that are fully recessed and concealed within the lower door bracket. The gravity activated cam assembly provides easy adjustment of door permitting it to rest at any desired open or fully closed position when not latched.

-Concealed latch assembly with stainless steel pin allows for emergency access. Cover plate and turn knob (#104) are heavy, non-ferrous Zamac castings with chrome plated finish. ADA lever handles are supplied on all handicap doors.

-Door strike and keeper (#105) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability.

-Combination coat hook and bumper for inswing door (#106) or double-prong coat hook for outswing door (#107) shall be cast Zamac with chrome plated finish. Door pull (#109) shall be supplied on all outswing doors. ADA doors receive door pull on both interior and exterior faces. Door bumpers (#108) provided where required.

Wall and Pilaster Brackets:

-Shall be heavy, non-ferrous Zamac castings with chrome-plated finish. The wall anchored pilasters and dividing partition panels shall be attached with two brackets of either double ear or single ear design depending on existing wall condition. Dividing partition panels shall be attached to the “rear” pilaster face with two “U” brackets.

INSTALLATION

Shall be in accordance with TDC’s approved shop drawing and installation instructions with partitions being rigid, plumb, straight and level. Unless stated otherwise, doors and panels are 58” high and mounted 12” above finished floor. Pilasters shall measure 82” from floor to top of headrail.

WARRANTY

Solid Plastic (HDPE)

Our High Density Polyethylene (HDPE) material offers the highest level of durability for high traffic areas. Waterproof, resistant to denting or vandalism, and impervious to humidity or corrosion, Solid Plastic partitions partitions are resilient, long-lasting and very simple to maintain. Material and color finishes offered are homogenous, not a surface application, so delamination is never a concern. A solid plastic installation is a great option for any high-volume washroom project.

COMPOSITION / CONSTRUCTION OF MATERIALS

All doors to be 1” thick by 55” high – All edges machine finished w/ ¼” radius

All panels to be 1” thick by 55” high – All edges machine finished w/ ¼” radius

All pilasters to be 1” thick by 82” high – All edges machine finished w/ ¼” radius

& include stainless steel adjustable leveling leg

All shoes to be 3” high and made of a one-piece molded plastic (color to match pilasters) OR

fabricated from 20 gauge type 304 stainless steel w/ #4 finish

All brackets to be 54” high and made of extruded PVC plastic (color to match panels) OR

1 ½” stirrup type brackets made from extruded aluminum w/ clear anodized finish (3 per connection)

All headrail to be clear anodized extruded aluminum with anti-grip design.

All headrail brackets to be fabricated of 20 gauge type 304 stainless steel w/ #4 finish

All fasteners to be stainless steel tamper proof security type screws.

FINISH

Toilet partitions shall be constructed of high-density polyethylene (HDPE) resins.

Partitions shall have homogenous color throughout with uniformly machined 0.25” radius edges.

All plastic components to arrive with a protective plastic masking

HARDWARE AND FITTINGS

HINGES: Doors are fabricated with an integral hinge system consisting of a pilaster machined to accept a door and hinge mechanism with no exposed metal parts. Integral hinges consist of a two piece cammed nylon pin at bottom of door and one 4” nylon pin at the top of door. Nylon pins are secured in place with stainless steel pins. Alternate design hinges to be 8” high wrap around type made from extruded aluminum w/ clear anodized finish. Both style hinges are designed for easy adjustment in the field to either a fully closed or partially opened position.

DOOR HARDWARE: Strike/keeper to be a heavy duty 6” high clear anodized aluminum extrusion with sound dampening rubber insert. ADA compliant slide latch to be clear anodized aluminum with a black anodized sliding insert. Slide latch to be equipped with angle bar for emergency access. Each door shall be supplied with one chrome plated zamac coat hook with bumper. Each handicap door shall be supplied with one chrome plated zamac pull handle.

INSTALLATION

Shall be in accordance with TDC’s approved shop drawing and installation instructions with partitions being rigid, plumb, straight and level. Unless stated otherwise, doors and panels are 54” high and mounted 12” above finished floor. Pilasters shall measure 82” from floor to top of headrail.

WARRANTY

All American guarantees solid plastic material against breakage, corrosion, and delamination for a period of fifteen (15) years. If materials are found defective during this period for any of the reasons listed above, the materials will be replaced free of charge. Warranty does not included installation errors, improper usage, or vandalism.

Plastic Laminate

The recommended choice when the emphasis is on aesthetics and affordability. The high-pressure plastic laminate finish is bonded under pressure to a solid, impact-resistant particleboard core. The smooth, resilient finish provides an easy-to-clean partition that is resistant to surface dirt, staining, and corrosion. Plastic laminate is available in an incredible range of colors and patterns to offer unlimited design flexibility for any new or existing washroom.

COMPOSITION / CONSTRUCTION OF MATERIALS

The core material of all Doors, Panels and Pilasters shall be constructed of 45-lb density, resin-impregnated particle board having flat, smooth surface characteristics. A decorative plastic laminate is then bonded under pressure to core material with a non-toxic, water resistant adhesive. No splices or joints in facing or core are acceptable.

Doors are 1” thick with all external edges and faces covered with decorative plastic laminate. All edge surfaces shall be applied prior to the overlapping face surfaces to seal edge and prevent laminate from being pried loose. Doors are pre-notched and recessed to accommodate concealed controlled gravity type hinges.

Panels are 7/8” thick with all external edges and faces covered with decorative plastic laminate. All edge surfaces shall be applied prior to the overlapping face surfaces to seal edge and prevent laminate from being pried loose.

Pilasters (Type H/B –Headrail Braced) are 1-1/4” thick with external edges and faces covered with decorative plastic laminate. All edge surfaces shall be applied prior to the overlapping face surfaces to seal edge and prevent laminate from being pried loose. Pilasters shall have adjustable floor anchor system including an integral jack-leveling device. A 3” high stainless steel shoe of one-piece construction, matching pilaster profile, shall be supplied to conceal floor anchoring. Tamper proof shoe assembly held in place by concealed floor anchor clips –exposed screws are not acceptable. Pilaster tops are securely braced together with a continuous anti-grip headrail of extruded aluminum alloy, polished and clear anodized.

FINISH

All components shall have edge and face surfaces covered with high pressure, .048 thick (general purpose grade) decorative plastic laminate that meets or exceeds NEMA standards for resistance to wear, burns and moisture.

HARDWARE AND FITTINGS

All material components are fully prepared to receive all necessary hardware and fittings. All door hinges, strike/keeper and brackets will be thru-bolted with sex bolts having theft resistant heads. Appropriate screws supplied for all other hardware and fittings. All fastenings to have a corrosion resistant finish.

Doors: All doors equipped with TDC “Duraglide” hinge sets.

-Upper and lower door brackets are heavy non-ferrous Zamac castings with chrome plated finish. Brackets are installed within factory pre-formed notches.

-Top hinge bracket (#102PL) is a heavy, non-ferrous Zamac casting with chrome plated finish. One-piece design has a 5/8” wrap-around flange that fits over the pilaster edge for maximum durability.

-Stainless steel 3/8” diameter pin (#101PL) goes through the door and the top hinge bracket for three-point bearing.

-Bottom hinge bracket (#103PL) is a heavy, non-ferrous Zamac casting with chrome plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability. Door operates on a stainless steel pintle and opposing nylon cams that are fully recessed and concealed within the lower door bracket. The gravity activated cam assembly provides easy adjustment of door permitting it to rest at any desired open or fully closed position when not latched.

-Surface mounted slide latch (#104PL) is heavy, non-ferrous Zamac casting with chrome plated finish.

-Door strike and keeper (#105PL) is a heavy, non-ferrous Zamac casting with chrome plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability.

-Combination coat hook and bumper for inswing doors (#106) or double-prong coat hook for outswing door (#107) shall be cast Zamac with chrome plated finish. Door pull (#109) shall be supplied on all outswing doors. ADA doors receive door pull on both interior and exterior faces. Door bumpers (#108) provided where required.

Wall and Pilaster Brackets:

-Shall be heavy, non-ferrous Zamac castings with chrome plated finish. The wall anchored pilasters and dividing partition panels shall be attached with two brackets of either double ear or single ear design depending on existing wall condition. Dividing partition panels shall be attached to the “rear” pilaster face with two “U” brackets.

INSTALLATION

Shall be in accordance with TDC’s approved shop drawing and installation instructions with partitions being rigid, plumb, straight and level. Unless stated otherwise, doors and panels are 58” high and mounted 12” above finished floor. Pilasters shall measure 82” from floor to top of headrail.

WARRANTY

TDC provides for all plastic laminated materials, when properly maintained, a one-year warranty against all defects in workmanship and construction under normal wear and use of this product.

Diamond Line

A unique textured metal with Diamond patterns available in a variety of colors for powder coated steel. A powder-coated steel installation offers remarkable quality and durability at an affordable price. A state-of-the-art electrostatic process applies a thermosetting powder coating to an electro-galvanized diamond textured steel partition, creating an installation that combines the strength of steel with a superior protective finish that resists fading, scuffing and staining. The same diamond patterned texture is available in our high quality durable Stainless Steel component. This attractive, durable material will suit any washroom design.

COMPOSITION / CONSTRUCTION OF MATERIALS

Doors are 1” thick, constructed with two 22-gauge sheets of stretcher leveled, commercial quality diamond textured electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Panels are 1” thick, constructed with two 22-gauge sheets of stretcher leveled, commercial quality diamond textured electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. All edges are then interlocked with a continuous roll-formed edge molding. All mitered corners are welded and ground smooth. Corner clips will not be acceptable.

Type H/B –Headrail Braced Pilasters are 1-1/4” thick, constructed with two 20-gauge sheets of commercial quality diamond textured electro-galvanized steel that are formed and then laminated under pressure to a sound deadening double-faced honeycomb core. Face plates are welded together at intervals of 18” on center around entire perimeter to insure a rigid one-piece unit. Edges are then interlocked with a continuous roll-formed edge molding. An inverted heavy gauge channel shall be welded into top of the pilaster for additional reinforcing. Pilasters shall have adjustable floor anchor system including an integral jack-leveling device. A polished 3” high stainless steel shoe of one-piece construction shall be supplied to conceal floor anchoring. Tamper proof shoe assembly held in place by means of concealed floor anchor clips –exposed screws are not acceptable. Pilaster tops are securely braced together with a continuous anti-grip headrail of extruded aluminum alloy, polished and clear anodized.

FINISH

Powder coated finishes are applied over diamond textured electro-galvanized steel containing a zinc coating thickness of .00015”. All components shall be cleaned and degreased prior to application of powder for maximum finish adhesion. A hybrid epoxy/polyester powder is then applied by an electrostatic painting system to ensure uniform thickness. Baking at 345 degrees for 22 minutes cures the finish.

HARDWARE AND FITTINGS

All material components are fully prepared with suitable internal reinforcement to receive all necessary hardware and fittings. TDC supplies factory pre-drilled components for a safer, more efficient and trouble-free installation. All door hinges and strike/keeper will be thru-bolted with sex bolts having theft resistant heads. Appropriate screws supplied for all other hardware and fittings. All fastenings to have a corrosion resistant finish.

Doors:

-Upper and lower door brackets are heavy non-ferrous Zamac castings that become integral part of door as they are imbedded within pre-formed abscesses at time of assembly. Powder coated finish shall match selected door color.

-Top hinge bracket (#102) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over the pilaster edge for maximum durability.

-Stainless steel pin (#101) goes through the door and the top hinge bracket for three-point bearing.

-Bottom hinge bracket (#103) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability. Door operates on opposing nylon cams that are fully recessed and concealed within the lower door bracket. The gravity activated cam assembly provides easy adjustment of door permitting it to rest at any desired open or fully closed position when not latched.

-Concealed latch assembly with stainless steel pin allows for emergency access. Cover plate and turn knob (#104) are heavy, non-ferrous Zamac castings with chrome plated finish. ADA lever handles are supplied on all handicap doors.

-Door strike and keeper (#105) is a heavy, non-ferrous Zamac casting with chrome-plated finish. One-piece design has a 5/8” wrap-around flange that fits over pilaster edge for maximum durability.

-Combination coat hook and bumper for inswing doors (#106) or double-prong coat hook for outswing door (#107) shall be cast Zamac with chrome plated finish. Door pull (#109) shall be supplied on all outswing doors. ADA doors receive door pull on both interior and exterior faces. Door bumpers (#108) provided where required.

Wall and Pilaster Brackets:

-Shall be heavy, non-ferrous Zamac castings with chrome-plated finish. The wall anchored pilasters and dividing partition panels shall be attached with two brackets of either double ear or single ear design depending on existing wall condition. Dividing partition panels shall be attached to the “rear” pilaster face with two “U” brackets.

INSTALLATION

Shall be in accordance with TDC’s approved shop drawing and installation instructions with partitions being rigid, plumb, straight and level. Unless stated otherwise, doors and panels are 58” high and mounted 12” above finished floor. Pilasters shall measure 82” from floor to top of headrail.

WARRANTY

TDC provides for all diamond textured powder coated materials, when properly maintained, a one-year warranty against all defects in workmanship and construction under normal wear and use of this product.